In today's fast-paced, technology-driven industries effective thermal management is no longer a luxury, it’s a necessity. Whether you're designing next-generation electronics, including AI/Telecom equipment, consumer electronics, medical devices—managing heat is critical to performance, safety, and longevity. That’s where thermal solutions manufacturing plays a pivotal role—and Jamcor Corporation is leading the charge.

At Jamcor, we specialize in advanced thermal solutions that help clients overcome the complex challenges of heat control in demanding environments. Our manufacturing capabilities are built around precision, scalability, and innovation. From prototyping to full-scale production, we support engineering teams with end-to-end services that ensure their thermal solutions are optimized from day one.

Why Thermal Solutions Manufacturing Matters

As electronic and industrial systems grow more powerful, they also generate more heat. Without proper cooling, performance degrades, components fail, and overall system reliability is compromised. That’s why thermal solutions manufacturing is essential to mission-critical industries such as:

- Computing and data centers

- Telecommunications

- Consumer and industrial electronics

- Automotive and electric vehicles

- Medical devices

Each of these sectors relies on precisely engineered thermal solutions like heat sinks, heat pipes, vapor chambers, and liquid cooling systems to ensure systems operate safely and efficiently.

Jamcor’s Commitment to Advanced Thermal Solutions

What sets Jamcor apart in the world of thermal solutions manufacturing is our integrated, engineering-first approach. We don’t just manufacture parts—we partner with you to solve complex thermal challenges. Our process begins with thermal simulation and analysis, allowing us to model heat flow, identify potential hotspots, and fine-tune the design for maximum efficiency.

From there, we move to rapid prototyping and scalable production, using state-of-the-art tools and processes like:

- CNC Machining – Ideal for custom, high-precision thermal components

- Extrusion – Cost-effective and scalable for high-volume heat sink production

- Metal stamping and forming – For lightweight, compact cooling components

- Skiving

- Cold forging

- Plastic injection molding – For integrated housing and non-conductive parts

- Assembly and QA testing – Ensuring your thermal products meet strict performance standards

These in-house capabilities allow us to control every step of the thermal solutions manufacturing process, guaranteeing consistent quality and rapid turnaround.

Core Products in Thermal Solutions Manufacturing

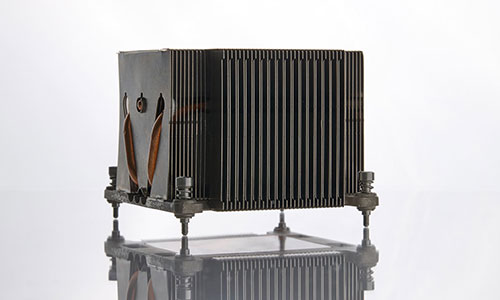

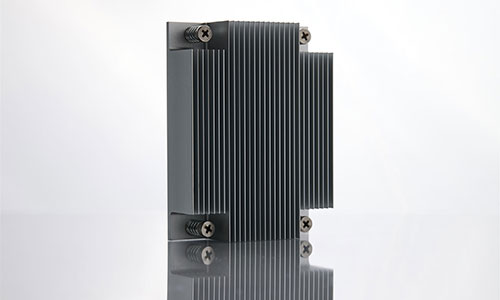

At the heart of advanced thermal solutions are the products themselves. Jamcor manufactures a wide array of cooling components tailored to meet the thermal needs of each application. Our core offerings include:

- Heat Sinks: Designed to absorb and disperse excess heat from power-intensive devices. Available in both extruded and machined formats, they optimize surface area, airflow, and performance.

- Heat Pipes: Using phase change principles (evaporation and condensation), they efficiently transfer heat from hot spots to cooler zones with minimal degradation.

- Vapor Chambers: Spread heat evenly in all directions (X, Y, and Z axes), ideal for high-wattage systems like CPUs, GPUs, and power modules.

- Oscillating Heat Pipes: Utilize capillary action and oscillating fluid movement to efficiently transfer heat across longer distances in electronics and industrial systems.

Whether it's a compact laptop or an industrial automation system, our thermal solutions ensure maximum reliability and performance.

Design for Manufacturability: A Key Jamcor Advantage

Thermal design is only one part of the equation—thermal solutions manufacturing must also be cost-effective, scalable, and repeatable. That’s why our design for manufacturability (DFM) approach is built into every project we take on.

Our engineers work closely with your team to balance performance with production efficiency. We optimize materials, simplify assemblies, and anticipate potential production challenges—reducing lead times and total cost of ownership. This is where our vertically integrated operation shines: we manage everything from material sourcing to final assembly under one roof.

Industry Applications for Thermal Solutions

The demand for advanced thermal solutions is growing in nearly every sector. Here's how Jamcor supports key industries:

- Consumer Electronics – Ensuring consistent performance in compact devices

- Telecom – Cooling base stations, servers, and 5G infrastructure

- Medical Devices – Reliable cooling for imaging and diagnostic equipment

- LED Lighting – Extending the lifespan of high-lumen fixtures

- Defense & Aerospace – Ruggedized components built to perform under pressure

- Automotive & EVs – Managing heat in battery systems, power electronics, and infotainment

These industries demand not just effective thermal solutions, but precision in their manufacturing. That’s why so many companies turn to Jamcor as a long-term partner.

Global Reach, U.S.-Based Quality

While Jamcor maintains strong global sourcing partnerships, all production and quality control operations are managed from the United States. This gives our customers the dual advantage of cost-competitive thermal solutions and domestic-level quality assurance.

By manufacturing locally and sourcing globally, we reduce supply chain risk and ensure rapid responsiveness—essential in today’s ever-shifting manufacturing landscape.

The Future of Thermal Solutions Manufacturing

As power densities increase and form factors shrink, the world of thermal solutions manufacturing continues to evolve. Jamcor is at the forefront of this evolution, investing in new materials, testing methods, and simulation tools to push the boundaries of what’s possible.

Emerging trends like liquid cooling, two-phase systems, and embedded thermal technologies are shaping the future—and we’re helping customers navigate that future with confidence.

Partner with Jamcor for Your Next Project

Whether you’re designing a new product or optimizing an existing one, Jamcor Corporation is the partner you need in thermal solutions manufacturing. Our experience, technical depth, and vertically integrated capabilities position us as a true extension of your engineering team.

We’re more than just a supplier—we’re your advanced thermal solutions partner from concept to completion.

Get in touch today to learn how Jamcor can deliver high-performance, cost-effective, and scalable thermal solutions for your next project.

Back to News