In today’s high-performance industries - from automotive electronics to telecommunications and computing — thermal management is not a luxury but a necessity. At the heart of effective thermal control lies the aluminum heat sink, a critical component engineered to dissipate heat efficiently and ensure operational reliability. In the evolving world of thermal solutions manufacturing, one method stands out for its superior results: cold forging aluminum.

As electronic devices become smaller, faster, and more powerful, managing the heat they generate becomes increasingly complex. Cold forged aluminum heat sinks are emerging as the preferred solution due to their superior thermal conductivity, mechanical strength, and production efficiency. At Jamcor Corporation, we specialize in manufacturing advanced aluminum heat sinks that push the boundaries of what’s possible in modern thermal engineering.

What Is Cold Forging Aluminum?

Cold forging aluminum is a metal-forming technique in which aluminum is shaped at or near room temperature using high-pressure compressive forces. Unlike hot forging or die-casting, cold forging maintains the structural integrity of the metal, producing dense, high-quality components with exceptional thermal and mechanical properties.

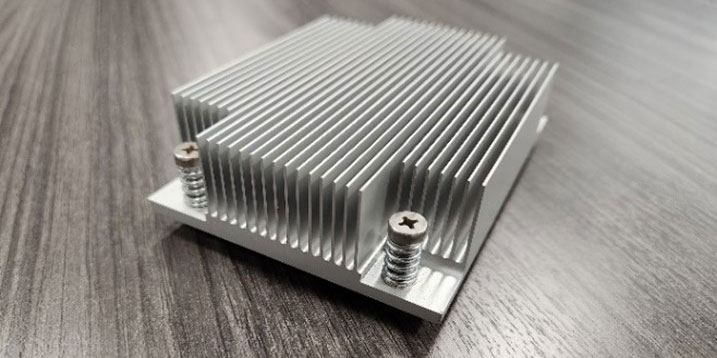

In the case of an aluminum heat sink, cold forging allows manufacturers to press the aluminum into intricate fin or pin shapes without compromising material density or introducing porosity. The result is a cold forged aluminum heat sink that excels in heat dissipation, durability, and consistency.

Why Cold Forged Aluminum Heat Sinks Are Superior

At Jamcor Corporation, we understand that not all aluminum heat sinks are created equal. The cold forging aluminum process offers several distinct advantages over other manufacturing methods like extrusion or die-casting. Here’s why more companies are choosing cold forged aluminum heat sinks as their go-to thermal solution:

1. Superior Thermal Conductivity

The cold forging process produces a tighter grain structure in the aluminum, enhancing its thermal conductivity. This means a cold forged aluminum heat sink can transfer heat away from sensitive electronic components more efficiently than its die-cast or extruded counterparts. This performance edge is critical in high-density systems such as CPUs, power amplifiers, and EV battery packs.

2. Higher Mechanical Strength

In addition to improved thermal properties, cold forging aluminum increases the material’s mechanical strength. This allows our aluminum heat sinks to withstand physical stresses and vibrations common in automotive, aerospace, and industrial applications.

3. Exceptional Surface Finish

Cold forged aluminum heat sinks typically exhibit a smoother surface finish, which not only improves aesthetics but also optimizes contact with thermal interface materials (TIMs). A cleaner surface allows for more efficient heat transfer, reducing thermal resistance and improving overall system performance.

4. High Aspect Ratio Fins

One of the key benefits of cold forged aluminum heat sinks is their ability to feature tall, thin fins. These high aspect ratio fins increase the surface area available for heat dissipation, making the heat sinks far more effective than traditional designs. This is especially beneficial in tight enclosures where airflow is limited.

5. No Porosity or Air Bubbles

Porosity is a common issue in die-cast components that leads to performance degradation over time. In contrast, cold forging aluminum ensures a void-free structure. The intense pressure used in the cold forging process eliminates any trapped air or impurities, resulting in a denser, more reliable aluminum heat sink.

6. Scalability for High-Volume Production

Thanks to its repeatability and precision, cold forging aluminum is ideal for scalable manufacturing. Jamcor’s vertically integrated production model allows for rapid prototyping and efficient mass production of aluminum heat sinks, helping customers meet aggressive go-to-market timelines without compromising on quality.

7. Integration With Other Thermal Technologies

Cold forged aluminum heat sinks can be paired with other heat transfer technologies like vapor chambers or heat pipes to boost thermal performance. This hybrid approach allows for customized thermal solutions that meet the unique needs of each application—from 5G telecom infrastructure to high-performance gaming consoles.

Jamcor Corporation: Engineering Thermal Excellence

What sets Jamcor apart in the competitive world of thermal solutions manufacturing is our commitment to technical excellence, scalability, and customer-focused engineering support. Our U.S.-based operations handle everything from design for manufacturability (DFM) and thermal simulation to CNC machining and final assembly.

Our extensive capabilities in cold forging aluminum enable us to deliver aluminum heat sinks that meet tight tolerances, exacting thermal requirements, and industry-specific performance standards. Whether you're developing consumer electronics or industrial control systems, Jamcor provides the thermal solutions you need to innovate with confidence.

Applications of Cold Forged Aluminum Heat Sinks

The use of cold forged aluminum heat sinks spans a wide range of industries. Here are just a few sectors where Jamcor’s thermal solutions are making a difference:

- Automotive: In electric vehicles (EVs), managing battery and power module temperatures is critical for safety and performance.

- Computing: High-performance processors and GPUs require reliable aluminum heat sinks to prevent overheating and maintain stability.

- Telecommunications: 5G base stations and network equipment generate significant heat, demanding efficient thermal designs.

- LED Lighting: LEDs are sensitive to temperature fluctuations, and cold forged aluminum heat sinks help maintain light quality and lifespan.

Cold Forging vs. Other Manufacturing Methods

| Feature | Cold Forging | Die Casting | Extrusion |

|---|---|---|---|

| Thermal Conductivity | High | Medium | Medium |

| Mechanical Strength | Excellent | Fair | Good |

| Surface Finish | Superior | Fair | Good |

| Porosity | None | Moderate to High | None |

| Fin Design Flexibility | High (Tall, Thin Fins) | Limited | Limited |

| Mass Production Compatibility | High | High | High |

The Bottom Line

When it comes to managing heat in today's most demanding environments, cold forged aluminum heat sinks deliver unmatched performance, reliability, and scalability. From design to delivery, Jamcor Corporation leads the way in thermal solutions manufacturing—equipping clients with the tools they need to keep their innovations cool, efficient, and competitive.

If you're seeking a long-term partner for your thermal management challenges, look no further than Jamcor. With our engineering expertise, vertically integrated production, and global sourcing partnerships, we ensure your aluminum heat sink needs are met with precision, quality, and speed.

Back to News